Crafter

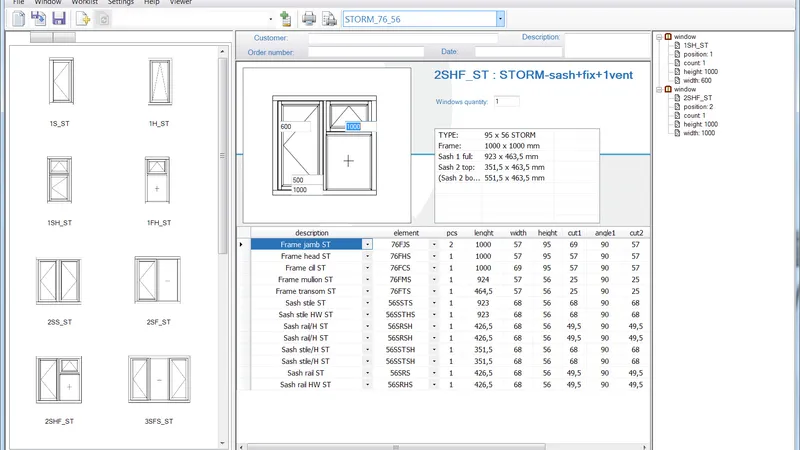

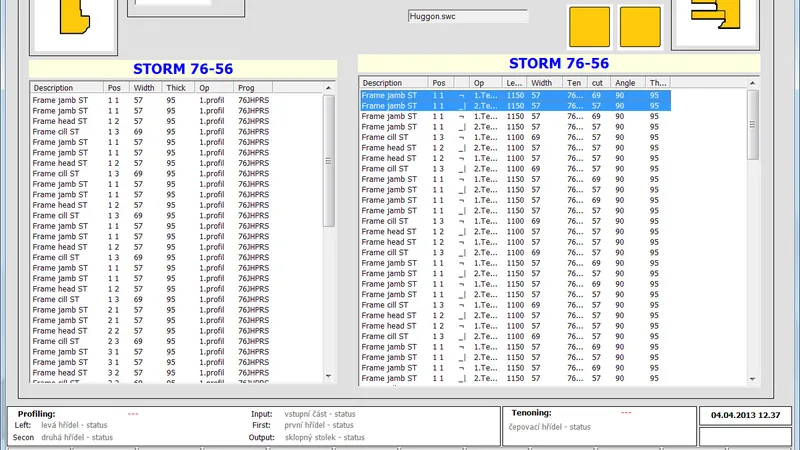

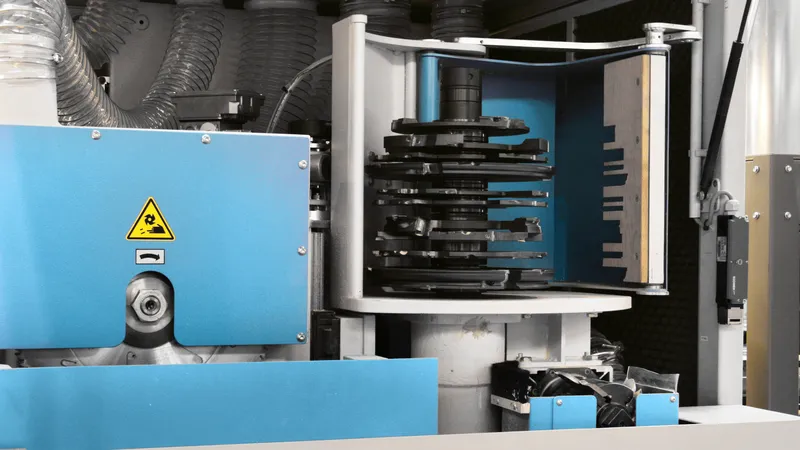

The compact window machining centre comprises CNC controlled tenoning and profiling shafts. The machine is controlled by a BECKHOFF industrial PC running specialised control software with an operator interacting with the machine via a 12" touch screen panel. The machine has been succesfully integrated with professional joinery software from Klaes and recently from Joinerysoft.

There are few new innovations such as a new software and shaft position control.

The CRAFTER CNC machining centre has been developed for small workshops focused on special types of windows, doors and conservatories.

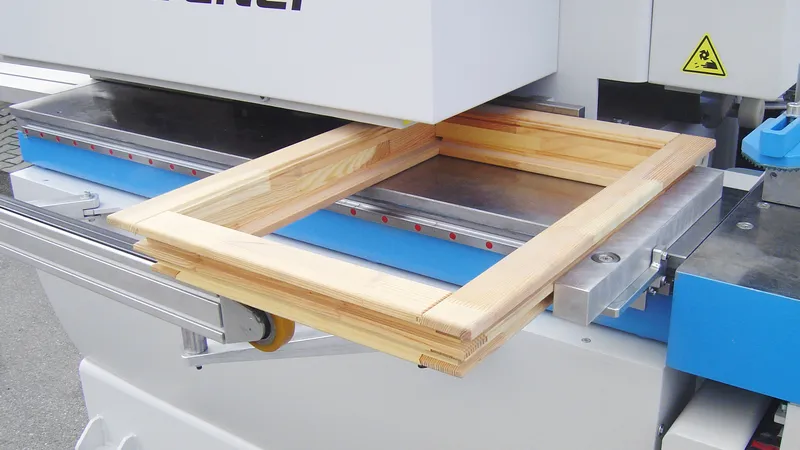

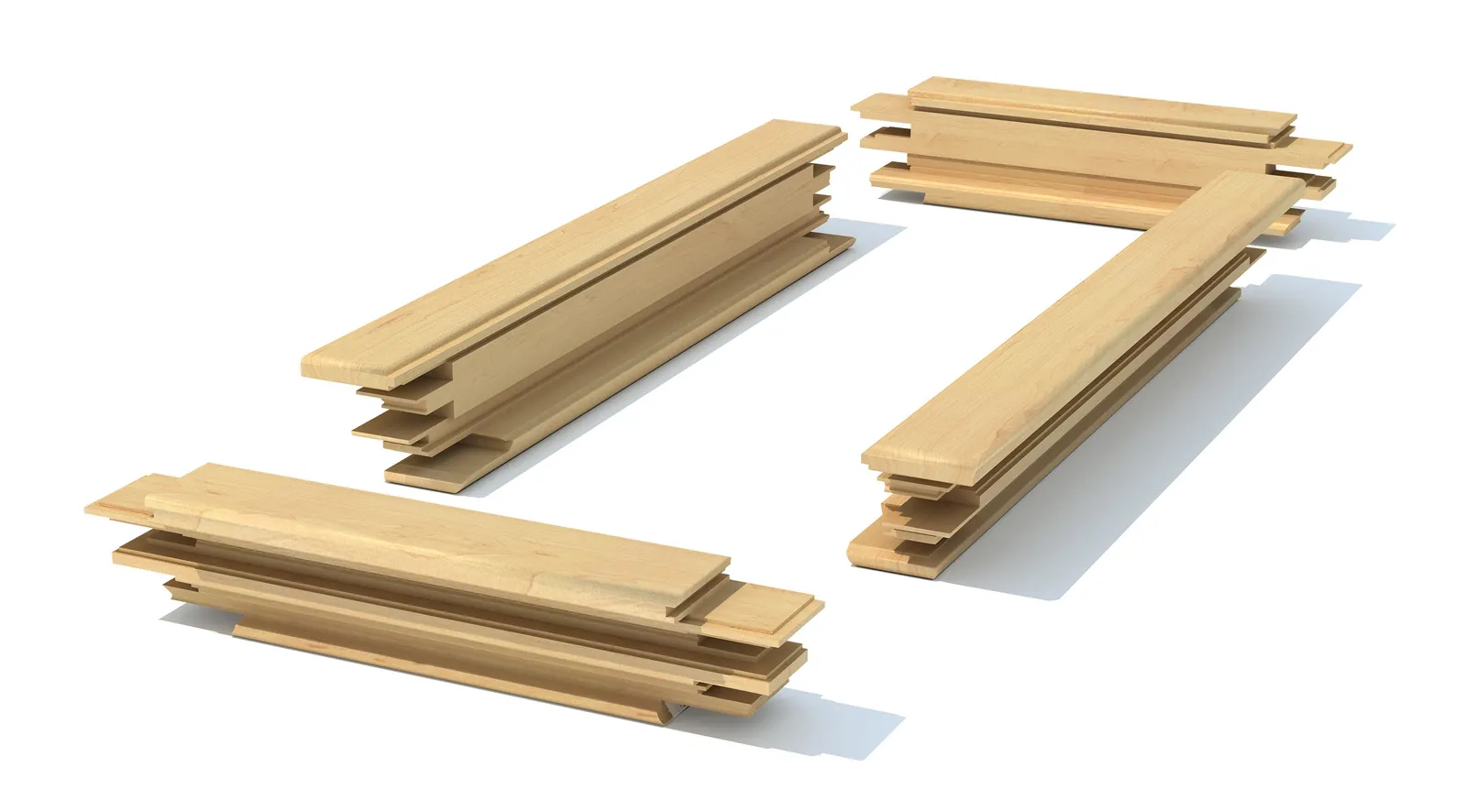

The UK SERIES is specially designed for manufacture of British windows. It is the only machine on the market optimized not only for casements but also for sliding sashes. The horizontal milling unit can easily provide the typical horns on sashes or trench slots for pulley stiles. The effective manufacturing of traditional boxes for sliding sashes includes the cutting operation for lining beads, pulley stiles, head and cill. A list of all components can be downloaded from the office design environment allowing the operator to easily supervise machining of the window components.

Integrating the CRAFTER with our WinCreator software offers you a new level of workshop organization. The capacity is about 15-20 one-leaf casements, 30-40 single sashes or 8-12 complete sliding sash windows.

The sliding sash operation

- open tenons and slots

- milling of horns in different moulds

- adapting of meeting rail slots to parting bead

- profiling of traditional bevelled meeting rails

- outside profiling and grooving for cord, gasket or balance springs

NB. Mortising of sash stiles is made off-line

The sliding box operation

- profiling of divided cill in part

- notching of cill part for interior lining bead

- trenching of slot in cill and head for pulley stiles

- cutting operation for moulded pulley stiles, lining beads, cill extension

- tenoning and profiling of box parts intended for balance springs

NB. Lining beads, pulley stiles, head and cill extension are moulded off-line

Casement operation

- recovering of glazing beads and sticking bars from frame rebate

- tenoning and profiling of frames

- tenoning and profiling of casements with shorted rails tenon for stormproofing

- tenoning and profiling of casements with full machining of components without stormproofing

(flush, stormproof & high performance windows)

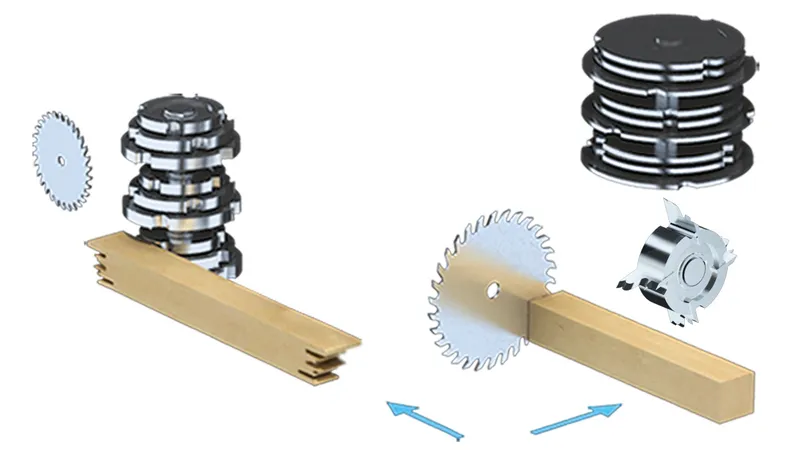

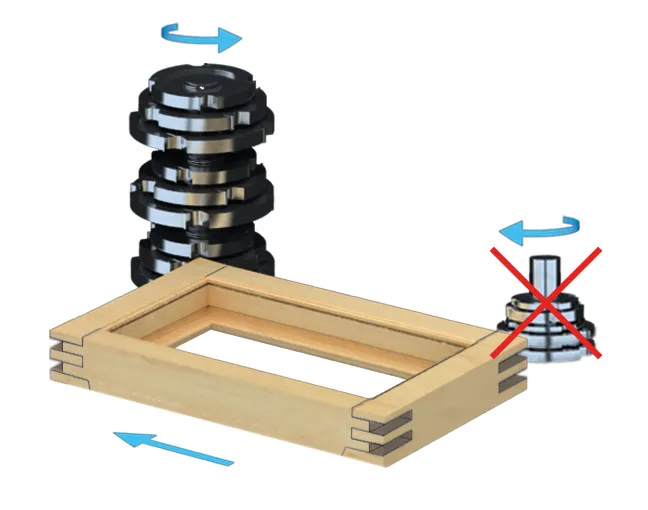

Configuration of the machine

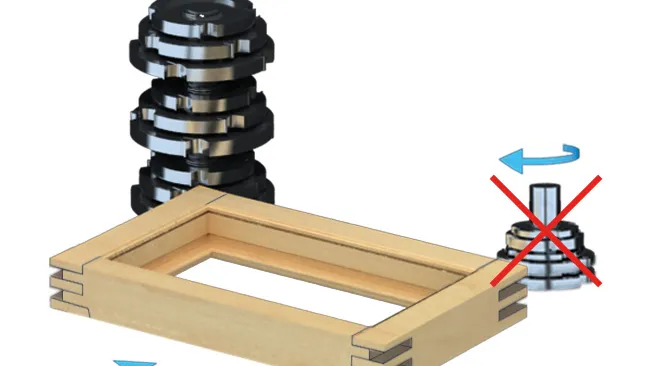

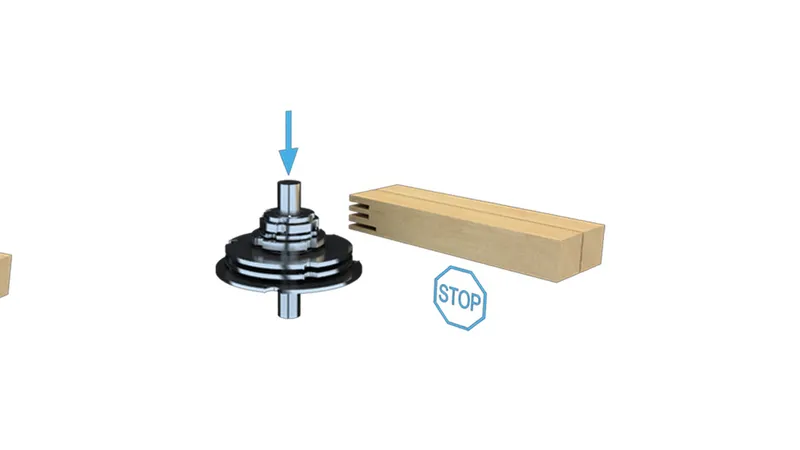

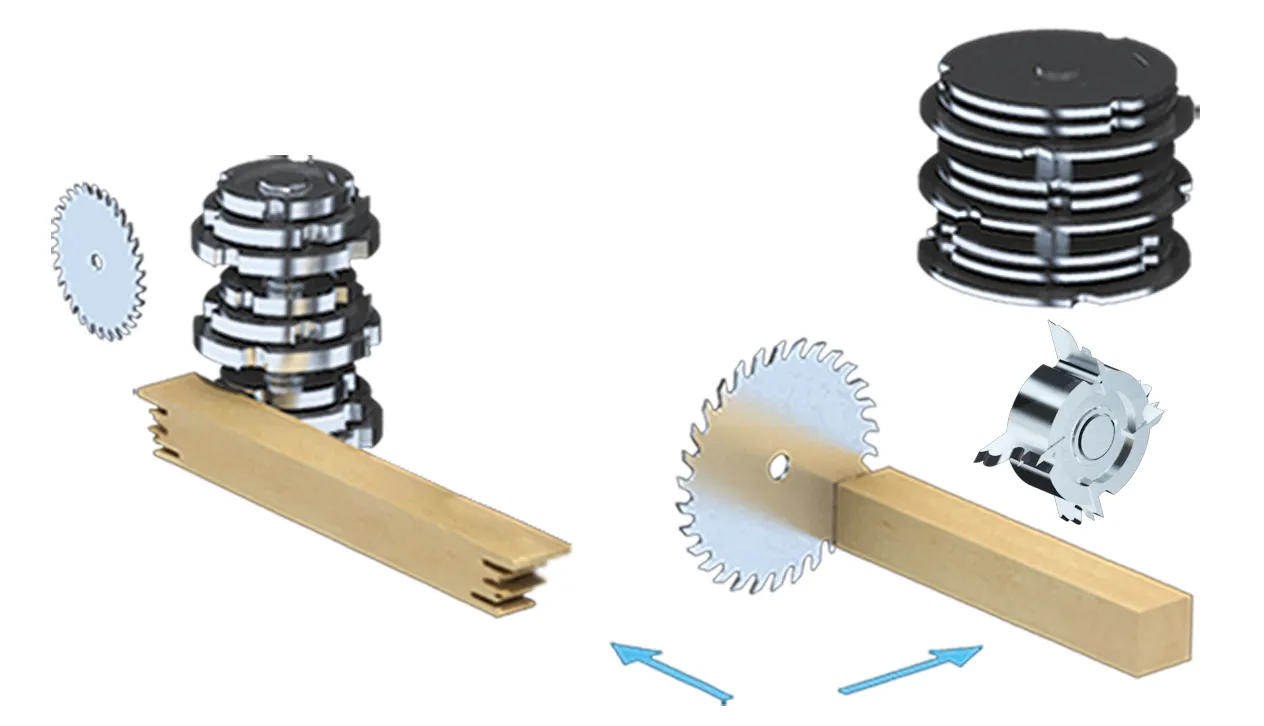

The original Soukup solution doesn’t need any antisplitting spindle jumping on the corner. The cross wood is milled out during the double cycle of tenoning. For outside milling remains only longitudinal wood without tearing off. This system makes milling of small sashes easier where the stability causes problem.

Horn unit on the tenoning side of the Crafter