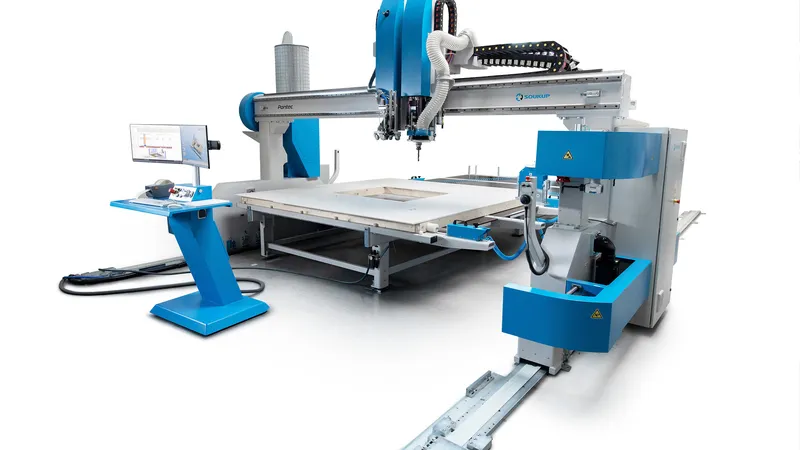

Pontec

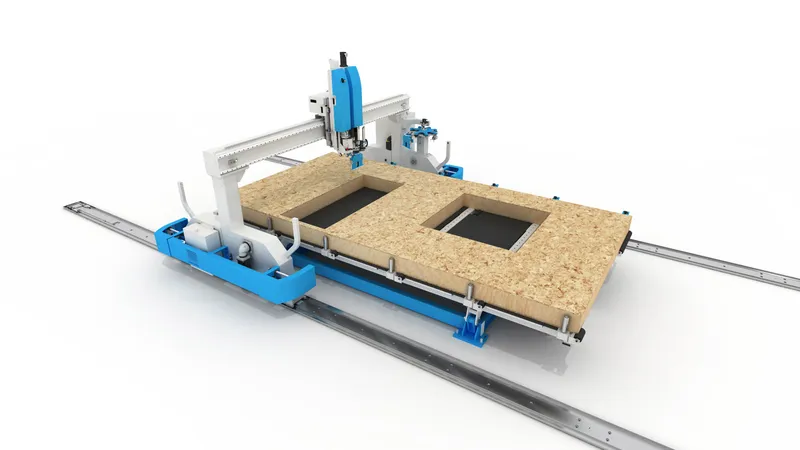

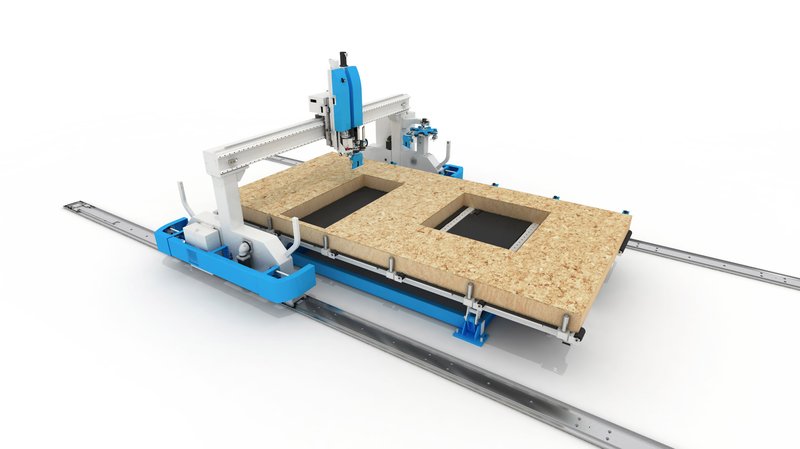

CNC multifunctional bridge

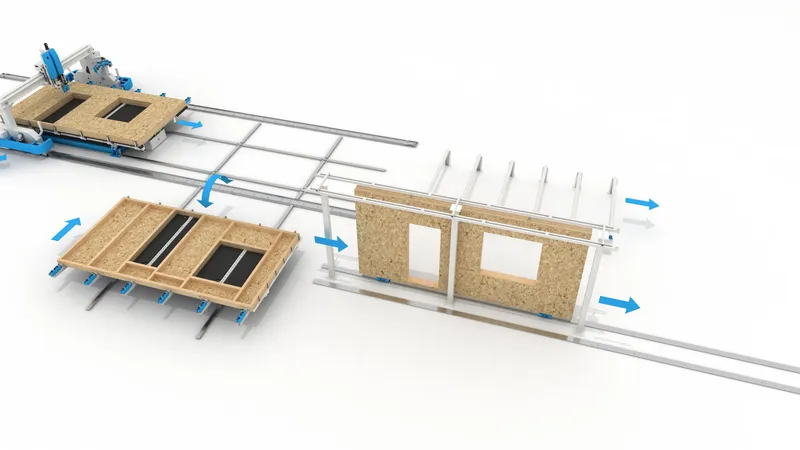

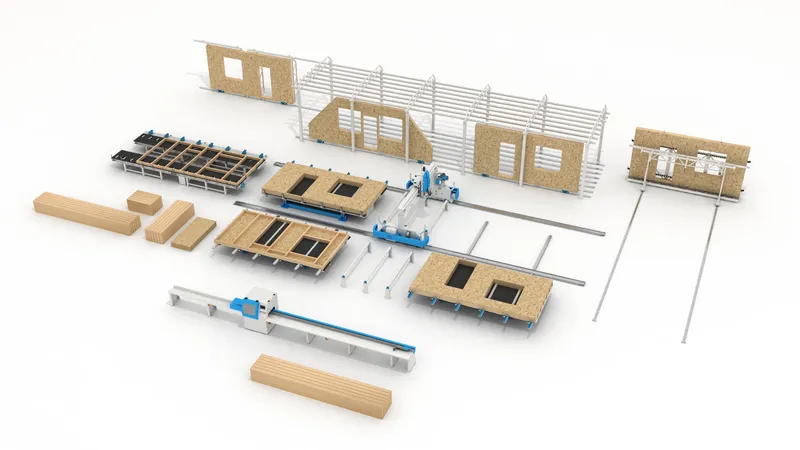

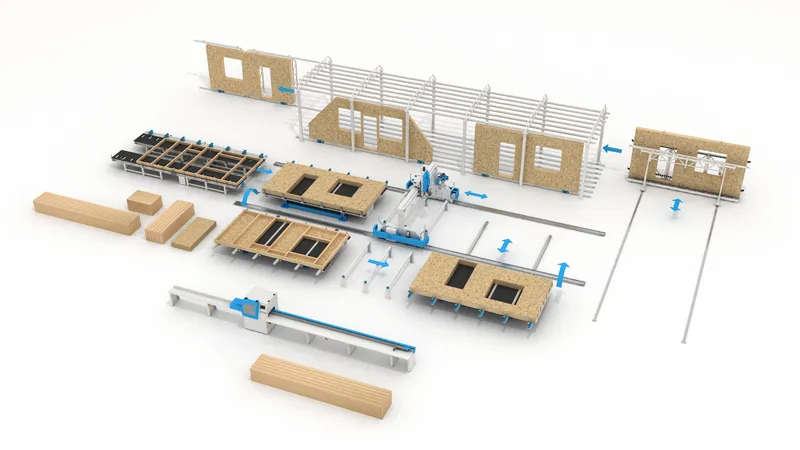

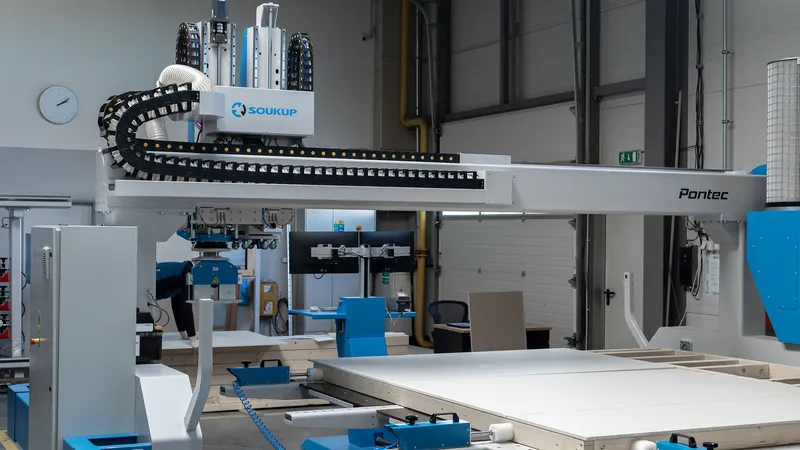

The multifunctional CNC-controlled bridge is designed for machining of panels of wooden buildings. The bridge works in combination with WING butterfly and transfer tables and allows work on both sides of the panels. It brings maximum productivity, sustainable quality and labour efficiency. The individual working units do the stapling of board sheets to the frame, formatting to the exact size, milling and drilling of all required construction holes. All this in a fully automatic process and with maximum accuracy.

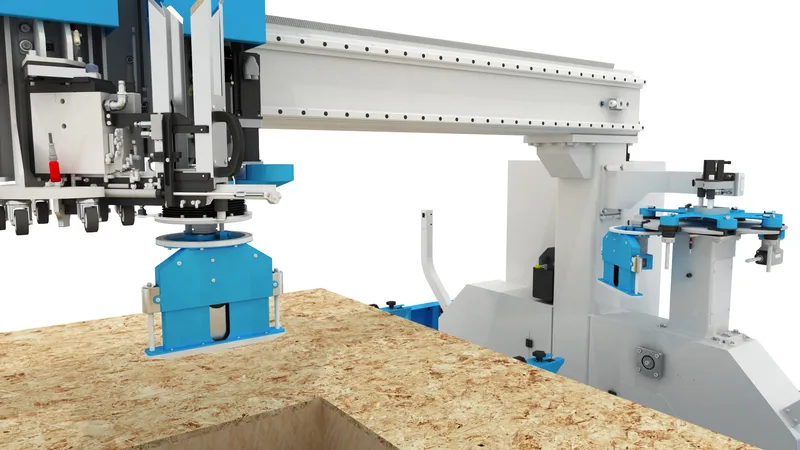

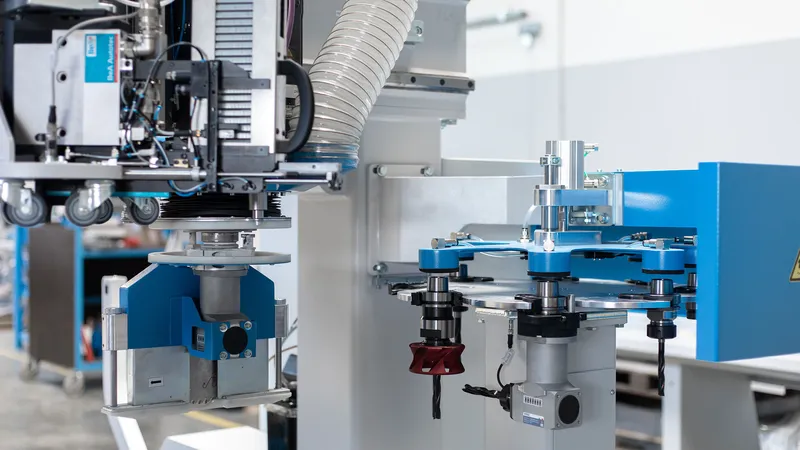

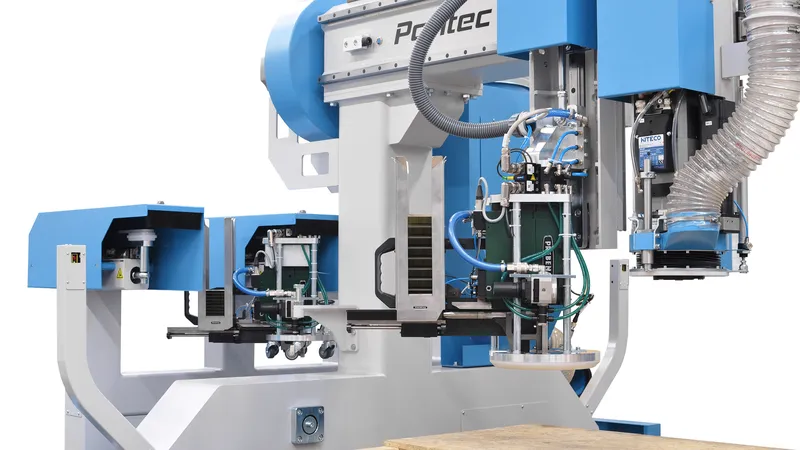

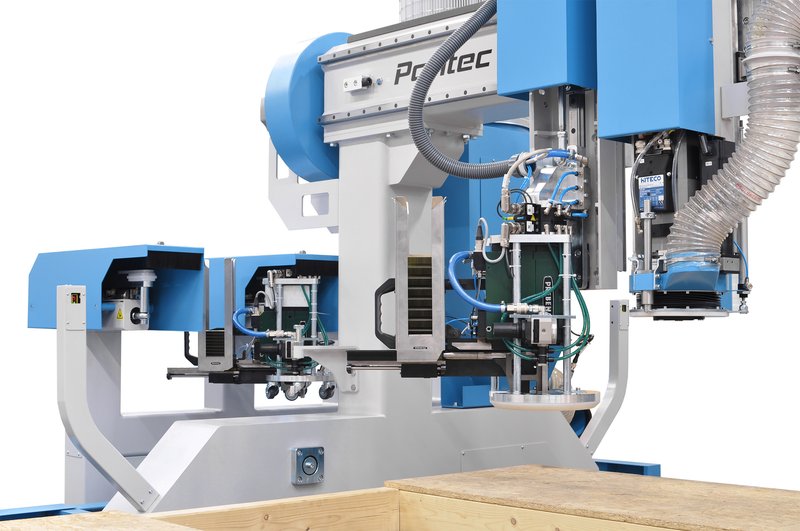

The concept of the Pontec machine is modular, variable, fully corresponding to the requirements of the proposed technology. The plant is already in its basic configuration equipped with a milling spindle with liquid cooling, with a C-axis for the use of aggregates, a rotary tools changer magazine for 8 tools.

There is also linear pneumatic aggregate magazine which offers space for 4 pneumatic tools. Selection and exchange of the required tool is automatic and program controlled. This addition to the PONTEC CNC portal provides the possibility of selecting from several types of fasteners according to the technological requirements of the design panels. The automatic changeover guarantees variability when using different types and lengths of staples and nails, even in the case of multi-layered compositions of different materials in a one panel..

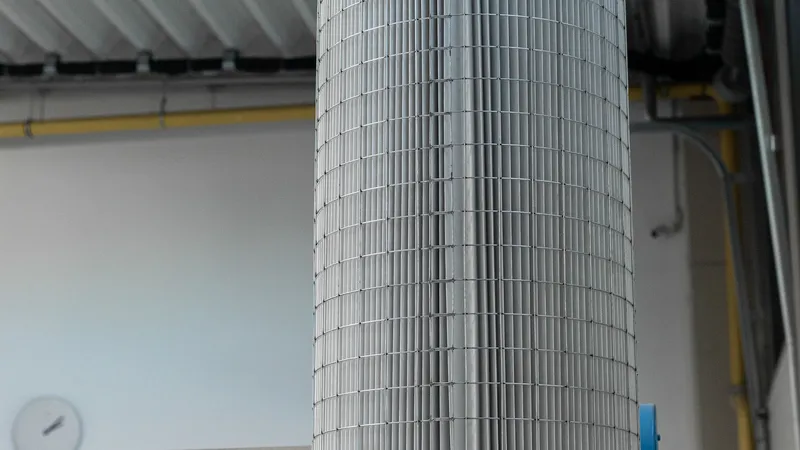

The device is supplied with an integrated extractor also suitable for gypsum fibre boards.

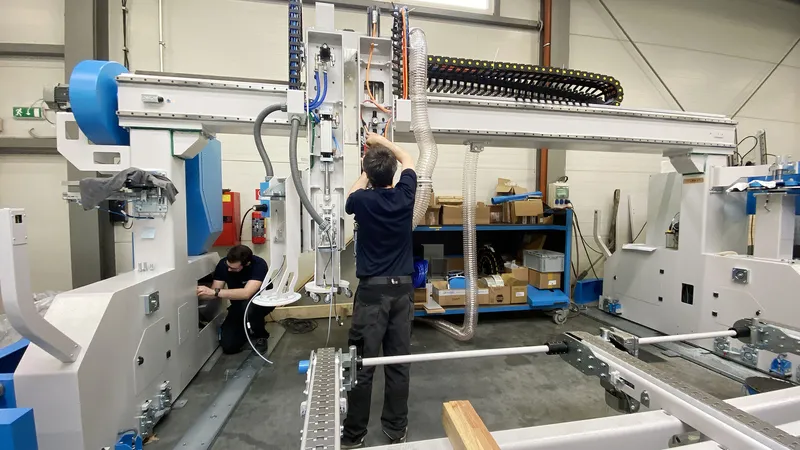

The robust construction corresponds to industrial use. Travel in the X-axis is by means of two synchronized servomotors with nylon belts. The Y-axis is guided in precise linear bearings with a rack and pinion drive. The milling unit is driven in the Z-axis by a servomotor with a ball screw, the stapler by a pneumatic piston.

The whole device is mounted as a part of an individually designed manufacturing line. Protective devices prevent collisions when entering the work area and stopping the machine when moving it.

Determination

- All types of wooden frame panels: wall, ceiling, roof, floor

- Suitable for panels with wooden and gypsum fibre cladding

Function

- Fully automatic control of the complete work cycle gradually performs all the necessary operations on the panel cladding specified in the program

- Stapling of board material to a wooden frame

- Perimeter formatting for:

- Cutting holes for construction fillings using a circular saw or rotary shank cutter

- Drilling and milling of required construction holes

Machine control

Project preparation before machining - PC office

- Loading work tasks in the form of a BTL file in the LIGNOCAM program environment

- Simulation of machine operation with the possibility of checking data before entering the machine

- Editing and modifying individual macro machining before entering the machine

Work on the PONTEC machine - integrated industrial PC Beckhoff with two large screen monitors; NCi control, TwinCAT 3.

- Import and check LIGNOCAM input files

- Editing and adjusting individual machining on the panel

- Start the machine duty cycle

- Checking the progress of work

- Diagnostics of processes and machine condition

- ON-LINE technical support from the manufacturer

Parameters according to manufactured panels

- Travel length - according to the project for tables 6; 9.6 and 12.8 meters

- Panel width - 3000 mm

- Panel thickness - 50 - 400 mm

Work units

Milling unit

- Power S1 - 8/9.5 kW, HSK 63 F

- Liquid cooling

- Spindle speed 0 - 24,000 rpm

- 360 ° C-axis for aggregates

- Automatic toolchanger with 8 positions for tools and aggregates

Tools and aggregates

- Spiral tool ø 16 mm, HSK 63F

- Saw unit ø 250 mm, HSK 63F with integrated extraction cover

- Additional tools and aggregates as required

Possible stapler units

BeA AUTOTEC 264

- Staple length 26-65 mm

- Magazine capacity 1900-2000 pcs

- Stapling speed 9 pcs / sec

BeA AUTOTEC 284

- Staple length 75-160 mm

- Magazine capacity 550 pcs

- Stapling speed 3 pcs / sec

PREBENA MODUL 11 - Q80 (Z80)

- Staple length 225-80 mm

- Magazine capacity 2520 pcs

- Stapling speed 9 pcs

PREBENA MODUL 11 - WP130

- Staple length 75-130 mm

- Magazine capacity 600 pcs

- Stapling speed 4 pcs